The Function of An Earth Anchor in Improving Structural Stability

The Function of An Earth Anchor in Improving Structural Stability

Blog Article

High-Performance Support Solutions for Any Type Of Application

High-performance anchor systems are critical in guaranteeing safety and security and security across a wide variety of applications, from construction to aerospace. Comprehending the subtleties of various anchor kinds and their respective setup methods is vital.

Types of Support Equipments

When considering the varied applications of anchor systems, what are the primary types that specialists rely upon for high-performance results? Anchor systems can be extensively classified into numerous kinds, each designed to meet certain requirements based on the nature of the load and ecological conditions.

The first category is mechanical supports, which consist of development supports, wedge supports, and screw supports. These are commonly used in concrete and stonework applications, supplying durable holding power with mechanical interlock or rubbing.

One more considerable type is adhesive supports, which make use of chemical bonding representatives to safeguard the anchor within the substrate. This type is particularly advantageous in applications where high tensile toughness and resistance to shear pressures are needed.

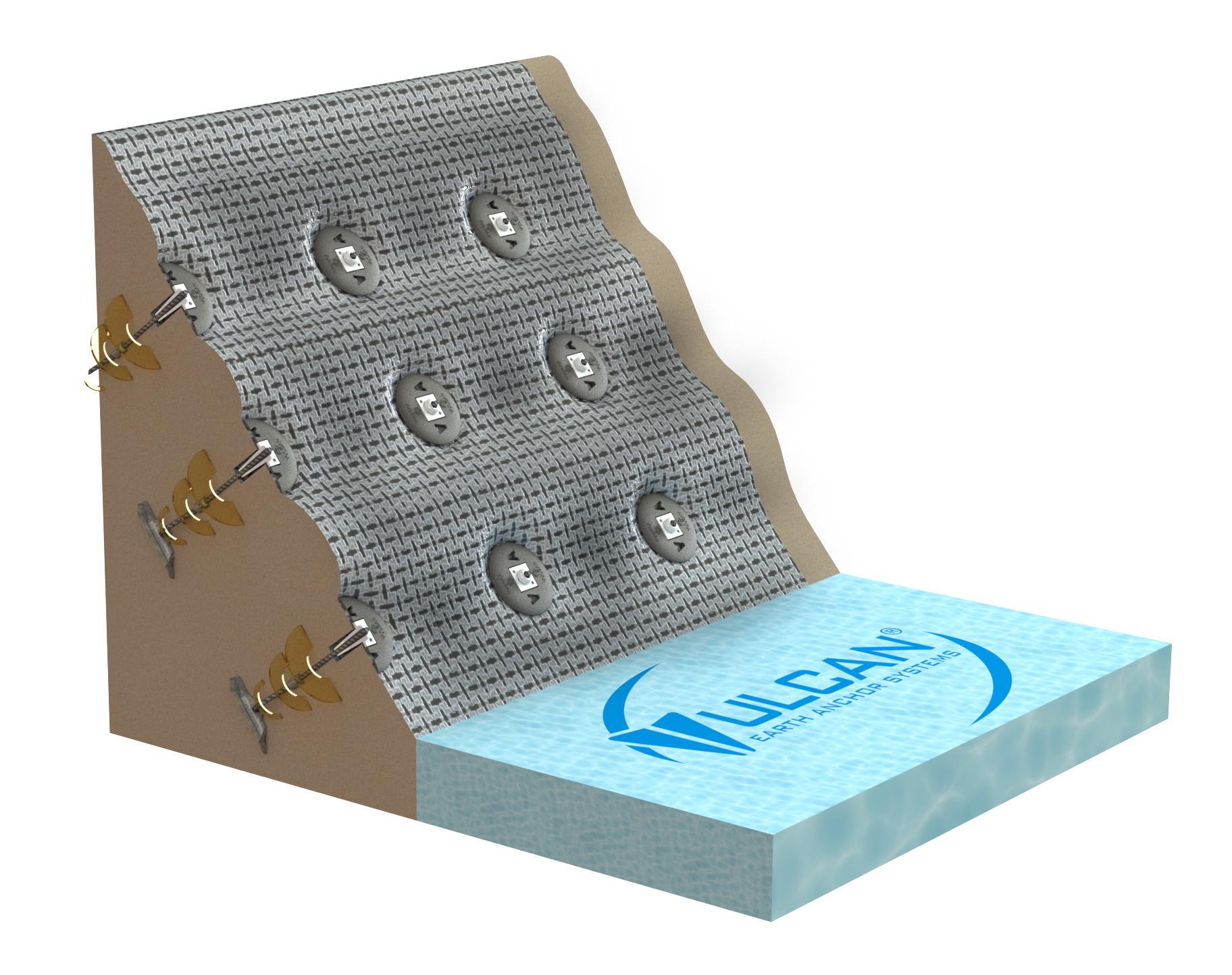

Furthermore, there are passive anchors, such as deadman supports, which depend on the weight and resistance of surrounding materials to secure things. They are typically utilized in outdoor applications or where vibrant tons are existing.

Lastly, there are specific anchor systems like ground supports, which are utilized in civil design and building projects for maintaining frameworks. Each sort of support system is created with specific efficiency metrics in mind, making sure optimal safety and security and effectiveness across various applications.

Trick Functions and Benefits

High-performance support systems offer a variety of crucial functions and advantages that enhance their performance in different applications. Among the main features is their superior lots capability, which ensures security and safety under considerable tension conditions. This is accomplished via sophisticated products and engineering layouts, permitting trustworthy efficiency in demanding atmospheres.

Additionally, these systems typically incorporate ingenious modern technology such as corrosion resistance and versatility to various substrates. This not just extends their lifespan however additionally lowers maintenance costs, making them an affordable option over time. The adaptability of high-performance anchor systems permits smooth integration into different frameworks, boosting their use across various jobs.

One more remarkable benefit is ease of setup. Many high-performance anchors are developed for simple and fast implementation, lowering labor time and increasing overall project efficiency. Their light-weight nature promotes transport and handling, contributing to streamlined operations.

Applications in Various Industries

In the transport sector, high-performance anchors are used to secure road and rail framework, adding to the security of vehicles and guests. Their integrity is paramount in stopping architectural failures that can cause tragic crashes. Furthermore, in the renewable energy sector, these anchors are critical for securing wind turbines and solar panel setups, guaranteeing they endure environmental tensions while making the most of effectiveness.

The aerospace industry also makes use of innovative securing solutions to secure components during manufacturing and transportation, where precision and dependability are imperative. In each of these applications, the selection of suitable anchor systems can dramatically impact general job success, highlighting the flexibility and requirement of high-performance anchors across various commercial landscapes.

Installment Strategies and Tips

Appropriate installation of high-performance support systems is vital to Get the facts their efficiency and durability. To guarantee optimum efficiency, it is vital to follow well-known setup techniques tailored to the details sort of anchor system and application.

Begin by extensively evaluating the installation website, including the substratum conditions, lots demands, and ecological aspects. Exact measurements and placement are essential; utilize laser levels or plumb lines to keep precision. When drilling, choose the suitable little bit dimension and type for the support system, ensuring precise and tidy holes to stop material damage.

Make use of the suggested torque setups during securing to prevent under-tightening or over-tightening, which can jeopardize the support's integrity. Furthermore, stick to the producer's standards regarding spacing and edge ranges to make the most of lots distribution and reduce possible failing factors.

Constantly employ personal protective devices (PPE) throughout the installment procedure, and consider using specialized tools created for high-performance anchors to boost performance and safety. Perform a detailed inspection post-installation to confirm that all components are securely fastened and in placement, guaranteeing the anchor system is ready to perform under anticipated lots.

Upkeep and Safety And Security Considerations

To guarantee the longevity and integrity of anchor systems, normal maintenance and safety factors to consider have to be prioritized. Regular assessments are necessary to identify deterioration, rust, or any architectural shortages that could endanger the anchor's efficiency. A see this site comprehensive upkeep schedule must include examining the integrity of support components, such as screws, welds, and plates, and ensuring that all links are safe.

Additionally, environmental variables can substantially influence anchor systems. Exposure to extreme weather condition problems or corrosive compounds can increase deterioration. Applying protective layers or utilizing corrosion-resistant products can boost sturdiness and lengthen solution life.

Safety considerations are vital; customers should stick to supplier guidelines regarding load limitations and operational procedures. Educating employees on appropriate usage and prospective dangers is critical in preventing accidents. Implementing a safety management system that consists of regular drills and feedback systems can grow a society of safety and security.

Verdict

In verdict, high-performance anchor systems represent a critical advancement throughout multiple sectors, supplying remarkable lots capability, deterioration resistance, and adaptability. Regular upkeep and complete evaluations further improve their efficiency, establishing these support systems as vital parts in protecting frameworks and equipment.

High-performance support systems are crucial in making sure safety and stability throughout a wide range of applications, from building and construction More Bonuses to aerospace.High-performance support systems offer a variety of vital features and advantages that boost their effectiveness in different applications. The convenience of high-performance anchor systems permits for seamless combination right into various structures, boosting their use across various projects.

In diverse sectors, high-performance support systems play an essential function in making certain structural integrity and security (Earth Anchor).In verdict, high-performance anchor systems stand for an important technology throughout multiple industries, offering outstanding lots ability, corrosion resistance, and flexibility

Report this page